Jr. Digital Fabricator-2024

(Entry Level Position)

Company Introduction

BWC Architects is an Oakland-based design-build architecture studio with a focus on creative renovations for Bay Area commercial and residential clients. Located 2998 Ford St., Oakland.

Job Description

We are currently offering full time & part time positions.

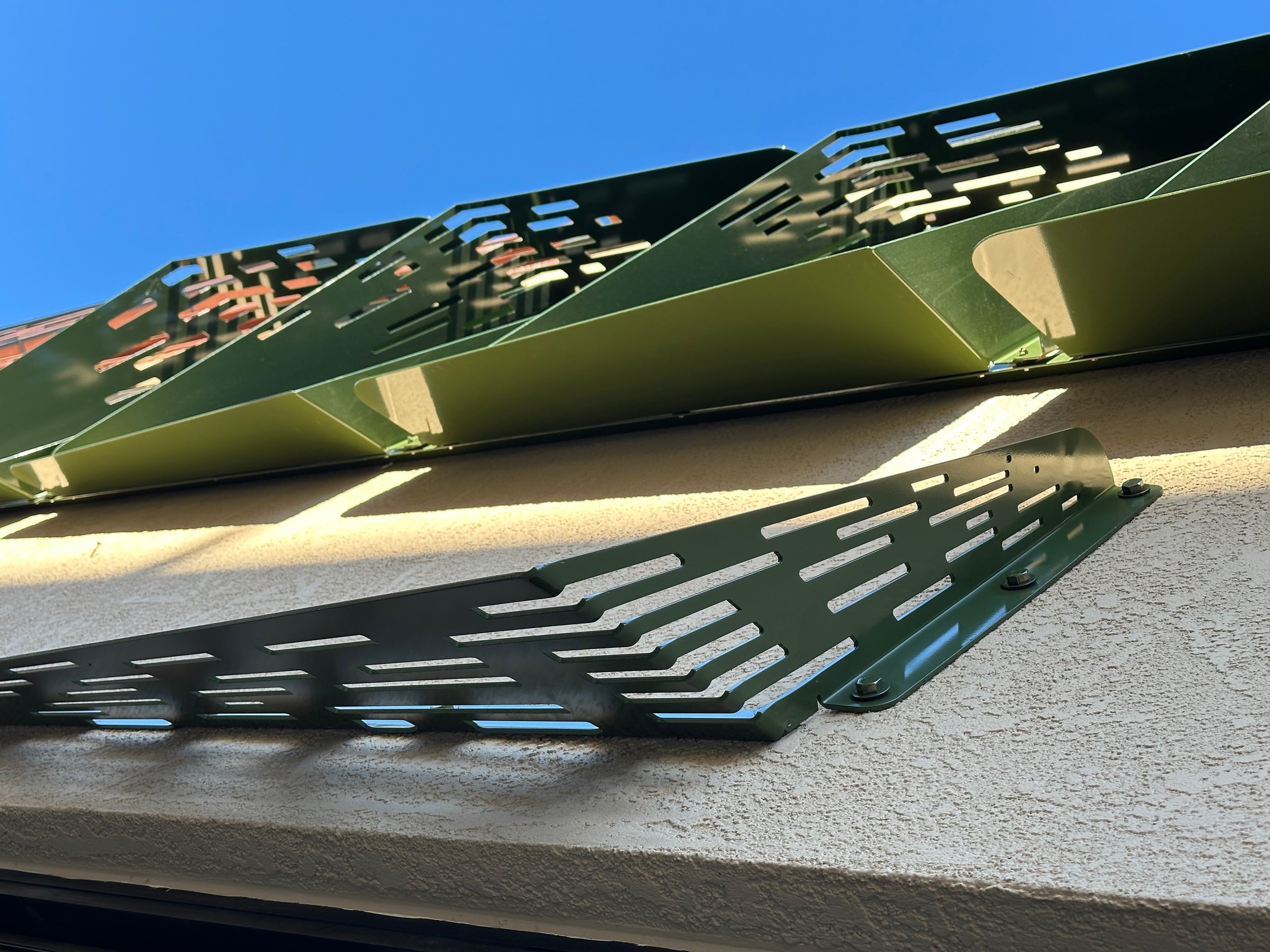

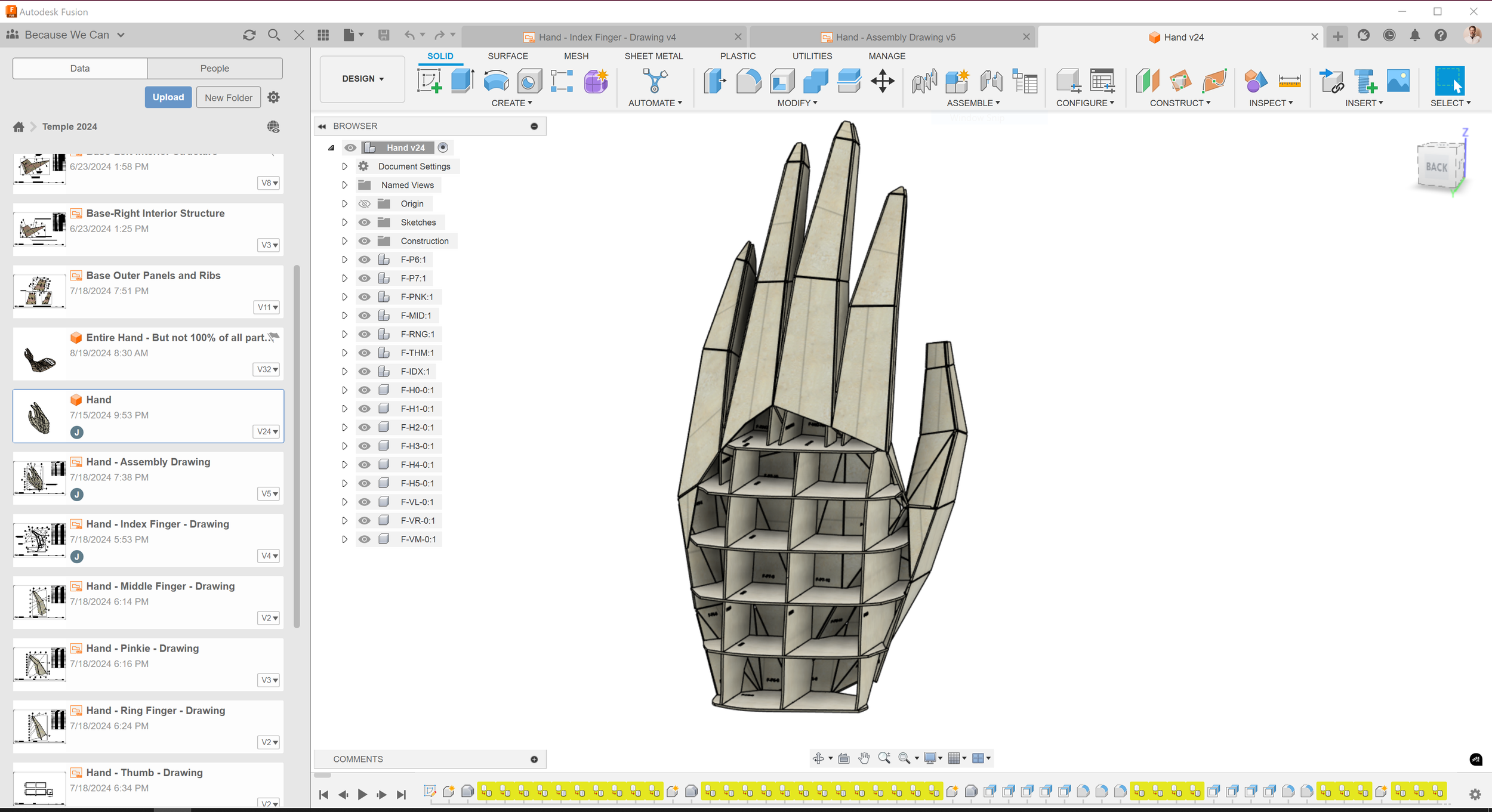

This role will be highly involved in the production of custom furniture and interior elements for our clients. Creative problem solving and self directed focus are key in this position, as well as an interest in being a multidisciplinary fabricator and learning new skills as we never make the same thing twice.

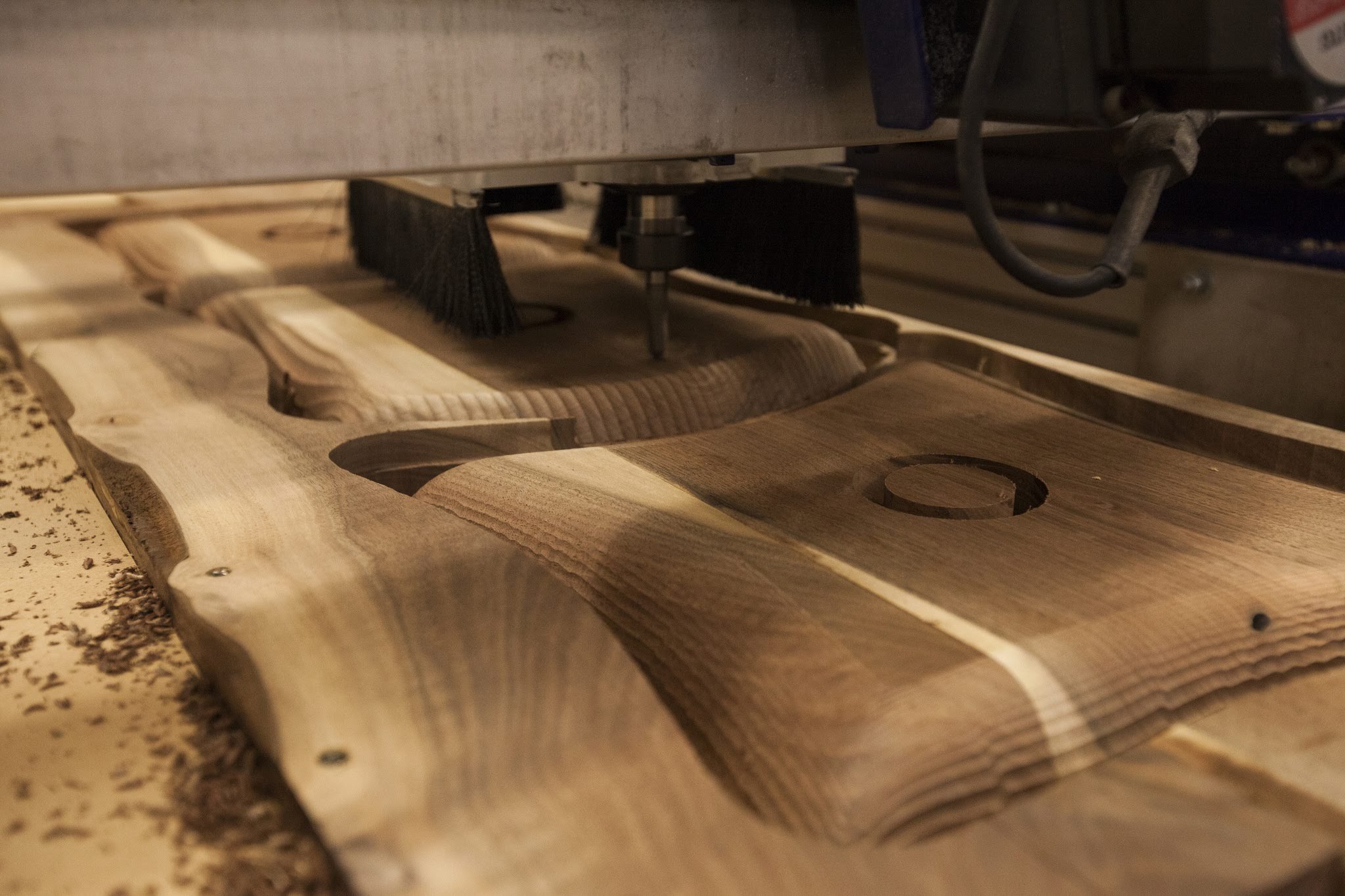

The perfect candidate is an up in coming, talented fabricator and crafts person who’s excited about fabrication, different materials, CNC manufacturing as well as hands on assembly and craft. We are passionate about quality and precision, and you should be too. You should have a desire to work in a fast paced production environment where your main job will be hands on making parts, assembling or finishing pieces.

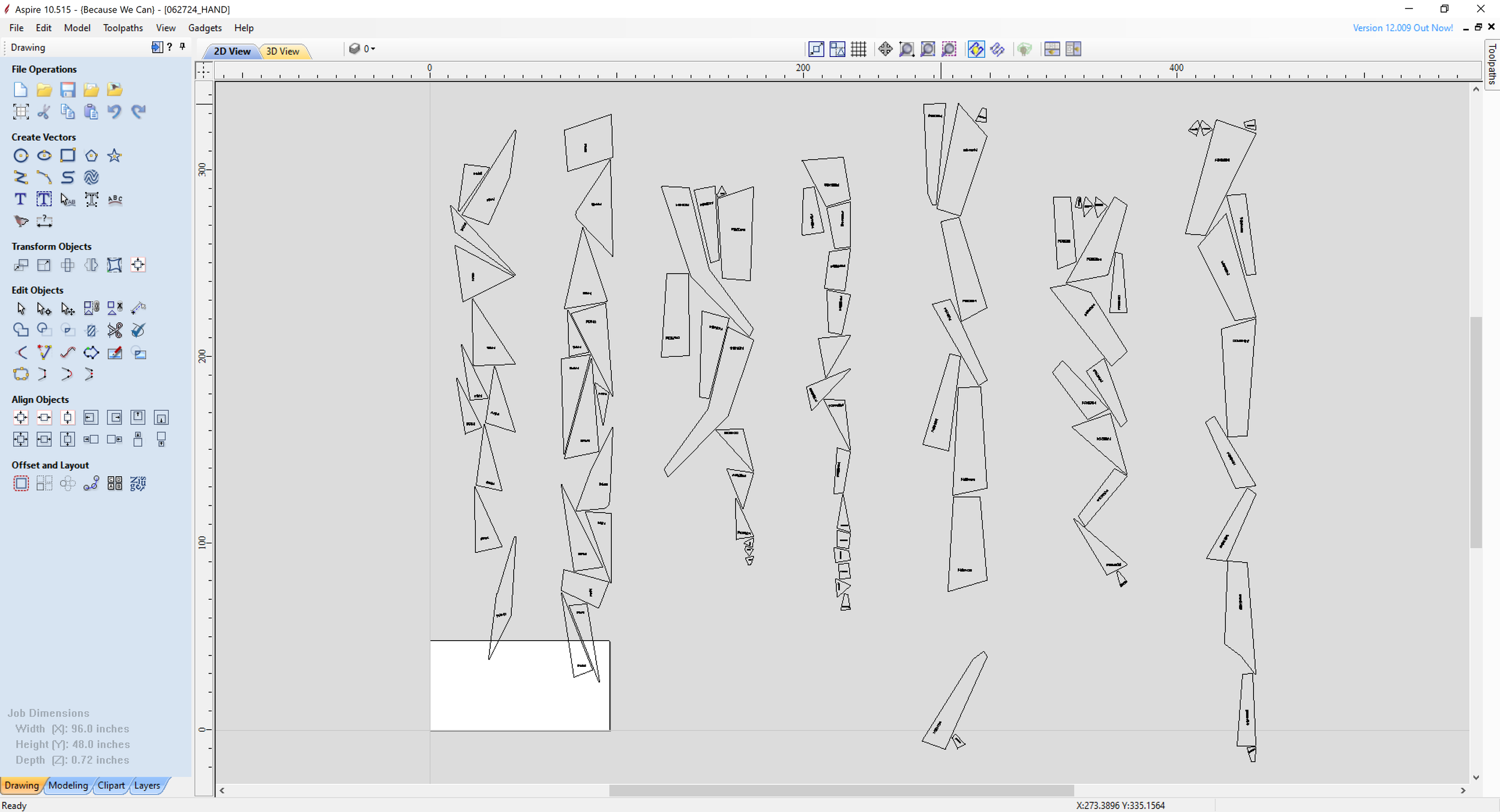

Main responsibilities will include running CNC routers, woodworking with hand tools, sanding, finishing, assembling and minimal onsite install. We also require daily clean up of the shop space and keeping a tidy workspace.

This position will work in a small team and solo.

Versatility is key in this fast paced and highly creative industrial shop environment.

We’re willing to train the right person on the various technologies, but applicants should have had experience with CNC machines and fabrication, assembly, sanding, working with hand tools and working with CAD/CAM software and/or 3D modeling software.

Responsibilities:

Operating CNC machines (after training)

Sanding/ finishing parts & assembly

Moving / lifting raw materials for job production

Maintaining a clean and organized work area & helping maintain the shop

Following shop safety standards and company operations manuals.

Required Skills:

Some experience in fabrication, construction, millwork, woodworking, or equivalent required.

Some demonstrated interest and ability in CNC routing and digital fabrication.

Attention to detail, organized, team player, and self motivated.

Comfortable working online for scheduling, task management, product info, email, chatting, etc.

Comfortable working in a dynamic, creative, fast paced and friendly team environment.

Ability to self direct & do research about materials, assembly, sanding & finish techniques on new materials

Benefits/ Pay Scale:

PTO plan (full time positions).

Medical and dental insurance (full time positions).

$22-$26 / hour depending on experience

Paid overtime hours

Bonus Points:

Please Apply with Resume and work examples to jillian (AT) BWCarchitects.com